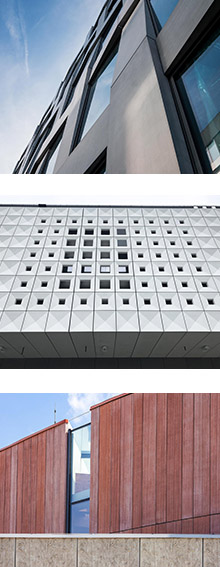

Facade cladding

The design of vented facades made of glassfibre reinforced concrete DAKO-GRC (formerly DAKOBET) will attract anyone who seeks simple minimalistic building concept and values high quality and durability of the final work. The collection of properties that are essential for such a work inevitably include resistance against mechanical damage (caused by piercing or breaking) and a long lifespan. According to the results of lifespan testing, DAKO-GRC facade panels retain their physical-mechanical properties for at least 50 years under normal outdoor conditions. The first known facade in 30 Cannon Street, London, made of GRC material has been around for 40 years, without the need for reconstruction.

As opposed to classic buildings with contact insulation the vented facade features an air gap between the outer cladding and the outer wall or thermal insulation layer. Owing to the gap, these objects are allowed continuous ventilation of the walls' surface.

Products of glassfibre reinforced concrete DAKO-GRC excel in distinctively lower weight in comparison to competing products. Another great advantage is the variability of elements – apart from classic cladding boards we are able to manufacture panels with solid corners, three-dimensional parts or architectural 3D motives, large format panels and design solitaires of a more complex shape.

Thanks to the use of matrices, it is possible to achieve a wide range of different surfaces and structures.

Surface finish

Glassfibre reinforced concrete parts are manufactured in two basic variations of surface finish – smooth panels are standard, another option includes products with a washed surface or “pepper and salt” effect. Thanks to the option of mass material colouring, an entirely individual colour design of final elements can be created upon a customer's request. Parts are treated with hydrophobic coatings before expedition that enhance their resistance against natural influences.

More information on surface finishing

Dimensions

Boards are tailor-made according to customer's requirements. Maximum board dimensions are not limited by production. Our domain is mainly large-format components with an area between 4 and 20 m2.

Anchoring

DAKO SMART

The DAKO SMART anchoring system of glassfibre reinforced concrete facades is based on the principle of integrating supporting parts directly into the panels during their production. The method of attaching the supporting frame to the glassfibre reinforced concrete part allows the panel to move during its reshaping due to external conditions. The use of DAKO SMART anchoring system brings many shape options in the design, as well as advantages in the subsequent realization. Therefore, the final shape of the facade is given only by the facade panels, which is beneficial particularly when designing a complicated architecture.

The integrated supporting frame ensures the rigidity of GRC panels in their entire area. It is, therefore, possible to produce parts larger than 3.5 m2 which can be easily manipulated with machines and then attached to a facade, without the risk of damage. Only a small telescopic crane is needed to handle the facade panels with a frame, and they can be installed with a significantly smaller number of workers than in the case of manual installation of otherwise anchored panels. The rectification system of the entire set will enable to attach the large-format panels accurately, even in the event of certain inaccuracies that occur on the construction site. Compared to other methods of panel anchoring, the combination of large formats, and quick installation is an economically advantageous solution for many projects, too.

The STUD-FRAME system is a variant of Smart anchoring where the integrated support enables anchoring of large-format parts, as well as of those more complex in form, without the need to install other subdesigns. The frame is spatially adapted to the shape of facade panels, and its rear part is parallel to the supporting structure of the building.

DAKO STANDARD

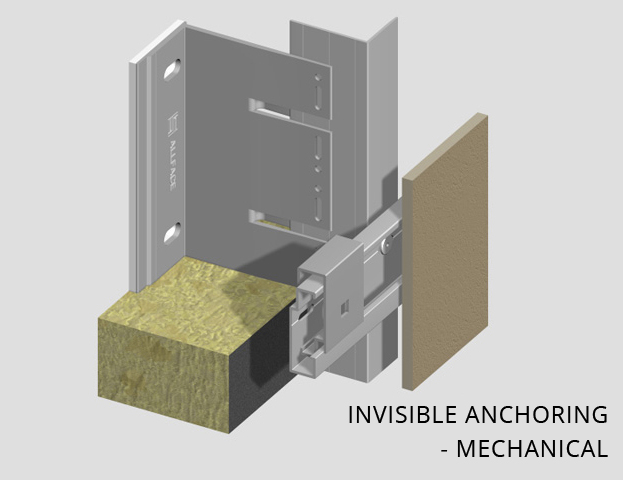

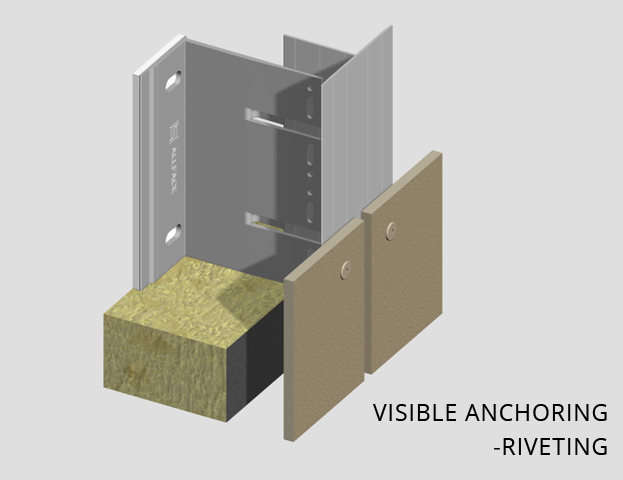

Mechanical

It is a fundamental anchoring method, mainly suitable for realizing facades of smaller cladding panels of simple shapes up to 3.5 m2 in size and up to 80 kg in weight. These limits arise due to manual handling and installing parts on the construction site.

Mechanical anchoring is based on the technology using a system of hidden hinges and screw anchors installed at the back side of a facade panel. An element is then fixed to a horizontal part of the supporting grate, its position at the facade is regulated by means of adjustment screws. In the last phase, the cladding is secured against shifting.

Construction details can be downloaded HERE.

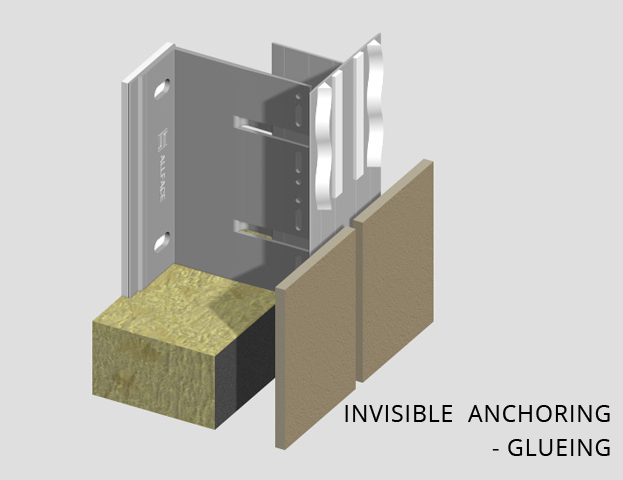

Glueing

It is the cheapest method of anchoring, especially suitable for the realization of facades made of smaller cladding panels of simple shapes up to 3.5 m2 in size and up to 80 kg in weight. These limits arise due to manual handling and installing parts on the construction site.

An alternative to hidden mechanical anchoring is glueing. The SIKA CZ company developed a system of facade board glueing SikaTack Panel that is suitable for creating vented facade structures both in the exterior and the interior.

Construction details can be downloaded HERE.

SUPPLIER INFORMATION

Price – to be assessed individually based on repeatability, shape demands and colours of required elements

Delivery time – depends on current production capacity. Not sooner than 28 days from production. The reason is maintaining the minimum setting time of concrete.

Storage – Parts are stored at roofed premises of a production hall

Formatting – After the parts have been set, they are formatted into required dimensions using a formatting CNC machine

Packaging – Flat facade panels on pallets, parts of miscellaneous shapes are transported loose. Higher quantities of panels are transported in a tailor-made transport boxes